By Piyu Dhaker, Applications Engineer, Analog Devices, North America.

Introduction :-Several industries such as beverage production, pharmaceutical plants, waste water treatment plants, and so on, rely on water quality monitoring systems to measure and control important water quality indicators. Parameters defining physical, chemical, and biological characteristics of water can be used as water quality indicators. Examples include: 8 Physical: temperature and turbidity Chemical: pH, oxidation reduction potential (ORP), conductivity, and dissolved oxygen Biological: algae and bacteria The article focuses on chemical measurement parameters that have been historically indispensable and unreliable, posing an implementation burden. Electrochemistry is a branch of chemistry that characterizes the behavior of reduction-oxidation (redox) reactions by measuring the transfer of electrons from one react antto another. Electro chemical technique scan be used directly or indirectly to detect and measure example water quality indicator spreviously listed. An electro chemical measurement system consists of two main blocks: Sensor: a device used to measure a water quality indicator and generate a corresponding electrical signal. Measurement and processing unit: circuitry that measures and processes the electrical signal. Typically, individual wired sensors are deployed across the processing plants. The in-field sensors need to be cleaned and calibrated frequently and replaced often. Wireless networks could reduce some of this burden, yet they are not typically considered robust enough to deploy in the harsh environment soft hese applications. In process, high reliability wireless sensing networks are now possible with new measurement and networking technologies. This article describes a demonstration platform that combines the universal sensor interface capability of the ADuCM355 and the wire-like reliability of Analog Devices’ SmartMesh®IP technology to form a robust and low power, wireless water quality monitoringsystem focused on pH measurement as the example water quality indicator. The principle can readily be extended to other electrochemical parameters to form a suite of water quality measurements for each wireless sensing node. pH Measurement and pH Probe The pH value is a measure of the relative amount of hydrogen and hydroxide ions in an aqueous solution. A neutral solution is one in which the hydrogen ion concentration exactly equals the hydroxideion concentration. pH is another way of expressing the hydrogen ion concentration, measuring acidity or basicity of the solution, and is definedas: pH = -log10(H+) (1) Where H+ is the hydrogen ion concentration in mol/liter. The pH value of a solution ranges from 0 to 14, with a neutral solution having a pH of 7, an acidic solution having a pH less than 7, and an alkaline solution having a pH greater than7. The pH probe is an electro chemical sensor consisting of a glass electrode and a reference electrode. When the pH probe is inserted in the solution, the measuring electrodegenerates a voltage that depends on the hydrogen ion activity of the solution, which is then compared to the potential of the internal reference electrode. The difference between the measuring and reference electrode is the measured potential and is expressed in the Nernst equationas: E= a- 2.303 R(T + 273.1) x (pH – pHISO) nF Where: E is the voltage of the electrode with unknown activity a = ±30 mV, zero point tolerance T is the ambient temperature in °C n = 1 at 25°C, valence (number of charges on ion).

F = 96485 coulombs/mol, Faraday constant R = 8.314 volt-coulombs/°K mol, ideal gas constant pH = the hydrogen ion concentration of an unknown solution pHISO = hydrogen ion concentration of the reference electrolyte; consult the probe documentation; typical pHISO =7 The equation indicates generated voltage that varies with the pH in a known manner. It also shows that the generated voltage is directly proportional to the temperature of the solution.As the solution temperature increases, the potential difference between two electrodes increases and vice-versa. An ideal pH probe produces ±59.154 mV/pH units at 25°C. Change in temperature can also change the sensitivity of the measuring electrode, which in turn causes measurement error. This error is predictable and can be accounted for by calibrating the probe across temperature, and then correcting for temperature during subsequent measurements. Typically, a temperature sensor is integrated into the pH probe. The temperature sensor could be a negative temperature coefficient (NTC) thermostat or RTD such as PT100 or PT1000. A pH probe with a temperature sensor. If the temperature sensor measures change in temperature, the correction factor is applied to the final pH reading, and the meter then shows a correctedand more accurate reading.This mechanism works well to compensate for any error in pH that can arise due to temperature variations.

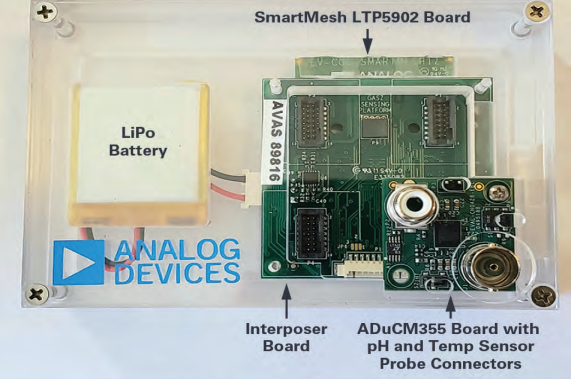

pH Measurement Unit with ADuCM355 is the industry’s most advanced and highly integrated chemical sensor measurement front end provides a platform solution for pH measurement with all the necessary measurement functions integrated with a low power microprocessor. The ADuCM355 enables a very low power measurement platform in a small form factor, making it small enough to be implemented inside the sensor housing while providing the capability and performance of benchtop instruments. Figure 4 shows ADuCM355’s pH measurement board with BNC and RCA connectors for pH probe and temperature sensor connections. This board is from the CN-0428 reference design.

Connecting pH Measurement Sensor Node to SmartMesh:- By combining the ADuCM355 with an Analog Devices SmartMesh transceiver, we created a small, low power pH measurement sensor node. The ADuCM355 provides measured pH data as a digital output.This digital data is then connected via UART to Analog Devices’ LTP5902 Smart Mesh IP wireless transceiver. The LTP5902 transmits digital data over Smart Mesh network to the Smart Mesh IP manager. SmartMesh is Analog Devices’ proprietary 2.4 GHz multihop wireless mesh networking solution based on IEEE 802.15.4e standards. It includes AES 128 encryption and authentication, providing robust end-to-end security. It is ultra low power and energy efficient, enabling each sensor node to run on batteries. SmartMesh networks communicate using a time slotted channel hopping (TSCH) link layer, which provides triple-play redundancy. The SmartMesh network manager (part of the gateway).

coordinates the schedule, manages security, performs over-the-air programming (OTAP), and automatically optimizes connectivity 24 hours a day, 7 days a week. The network manager also provides detailed network health reports via an API. For small networks, one embedded manager can support up to 100 sensor nodes (also called motes). Truly enormousinstallations of up to 50,000 nodes are supported with V Manager. Rigorous network stress testing ensures >99.999% data reliability, making SmartMesh the perfect solution for industrial wireless sensor networks that must maintain high network availability and not lose packets.Each sensor node consists of an offthe-shelf glass electrode pH probe with an integrated temperature sensor connected to ADuCM355 and SmartMesh IP mote. The pH probe senses the pH; ADuCM355 performs the measurement and calculations, and provides measured pH in digital output, which is then transferred over the wireless SmartMesh network to the SmartMesh IP manager. SmartMesh IP manager connected via USB to thePC. A gateway in this system is performed by a PC.This PChasNode-Red and SmartMesh SDK installed.The SmartMesh SDK issued to create a JavaScript object notation (JSON) server for the data, which is connected to Node-RED. Node-REDisused to display measured pH data from eachsens or node and allows connection to cloud services like IBM Watson, Amazon AWS, etc.

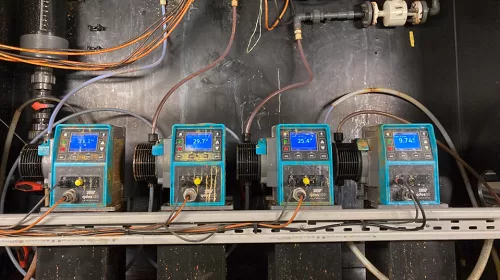

Hardware Setup For demonstration purpose, we are using a staggered three chamber fish tank with water flowing from the top to subsequent chambers. A pH sensor probe is immersed in each chamber. We have a fourth sensor placed in a reference solution at a distance to illustrate SmartMesh wireless communication over distance. As we change the pH of the solution in the top chamber, the data on NodeRED is updated, indicating a new phi As this new pH solution flows from the top to subsequent chambers, the other two pH sensors update their measurements and the data is displayed on the screen. Since the fourth sensor is immersed in a reference solution with no pH change, the readings from this sensor are constant. More information on Node-RED and measured data is provided in following sections. You can also view the demo recording here. Measurement Data: pH measurement from 4 sensor nodes is displayed on the PC using Node-RED. Node-RED is a programming tool with a web-based browser that allows connection of hardware devices, APIs, and other online services together.

Conclusion This article describes the wireless water quality monitoring system using Analog Devices’ ADuCM355 and Smart Mesh IP technology.The small form factor and low power features of these Figure 8. Wireless water quality monitoring system using ADuCM355 and SmartMesh. products allow the sensor node to be powered by a battery.Ro bust Smart Mesh technology reliably transfers data, even in harsh external environments. The demonstration illustrates a highly reliable wireless monitoring system and connectivity to cloud. This has tremendous potential depending on the end application, as this technology allows for monitoring of water quality at a location that is hard to reach, enables users to create alarms and warnings for different water quality thresholds, and leverages data to get more robust and better information about the continuous water quality .

Acknowledgements The author would like to thank Scott Huntand Bill Lindsay for their assistance during the demo development and also for taking time to review the article. I would also like to thank Dan Braunworth and Dan Burton for reviewing and proofreading the article, and sharing their insights on thearticle.